WIP - XVIIIb longsword

Apr 20, 2014 14:52:08 GMT

Post by Lukas MG (chenessfan) on Apr 20, 2014 14:52:08 GMT

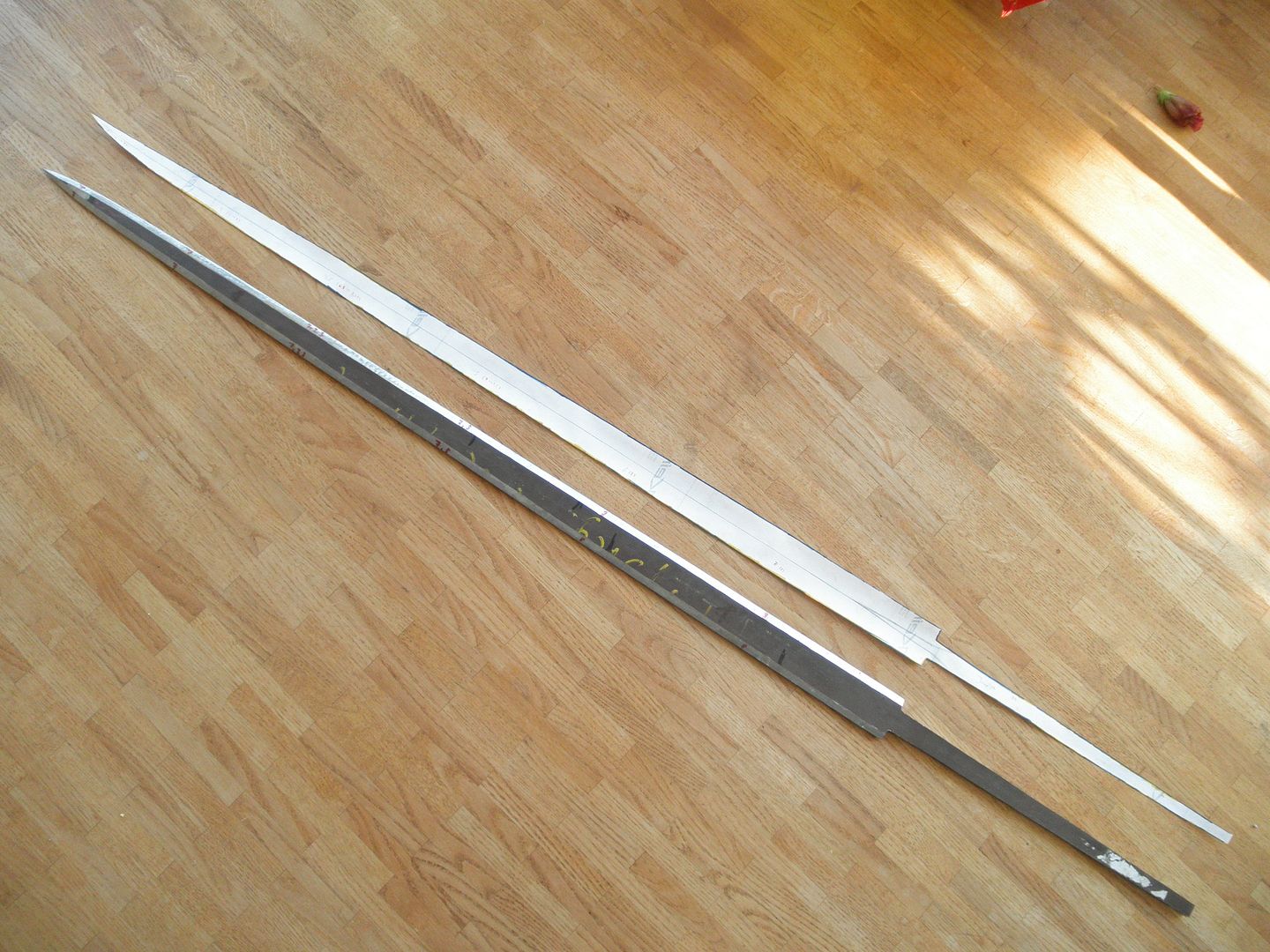

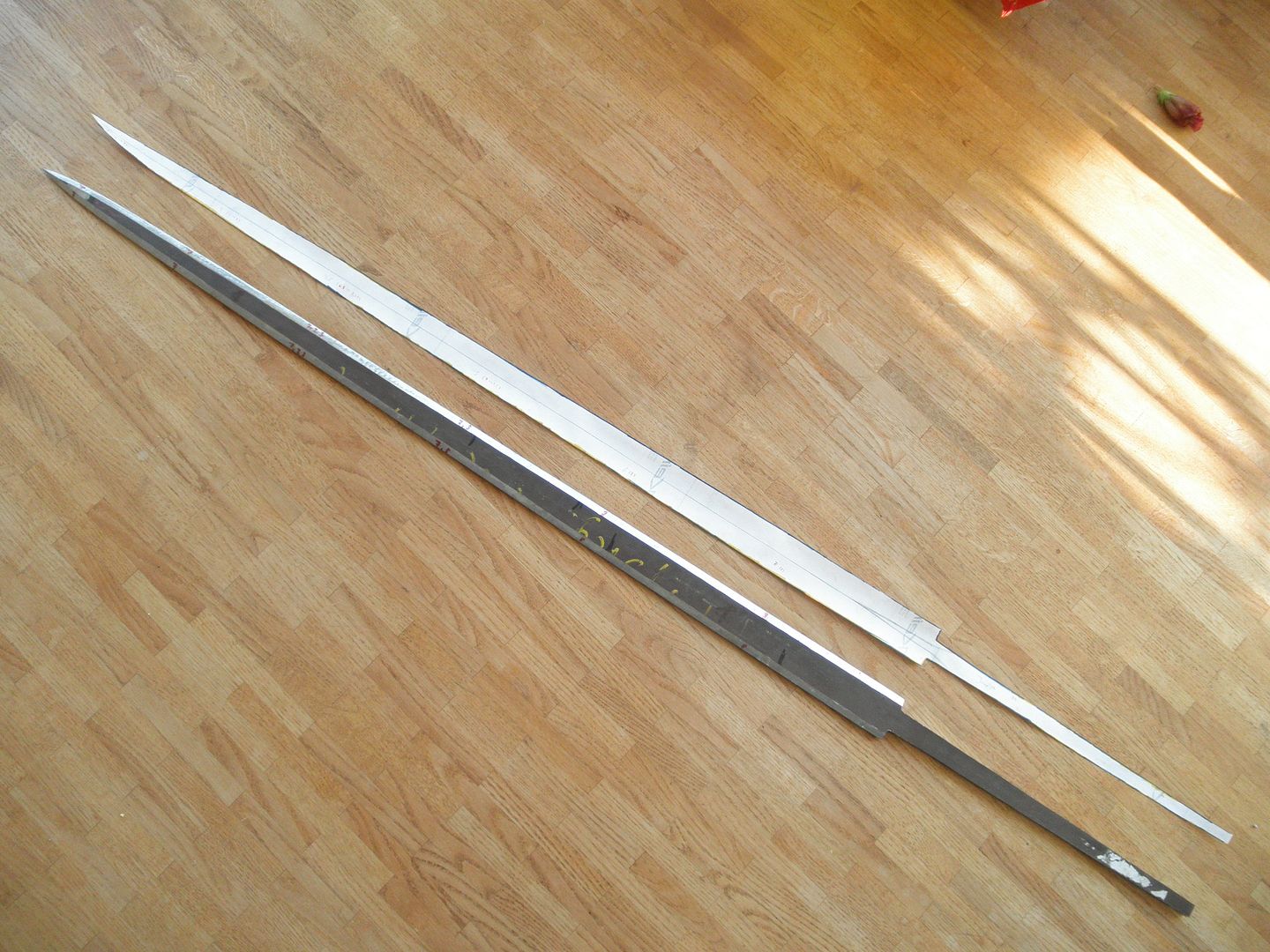

Since the first couple stages of blade making weren't recorded when I made this sword, I will add a few pics to fill in the blanks, so you get a complete picture of how I go about this. These pics are of two very similar but overall even bigger longswords I'm currently making. I put my sword next to the blank(s) to show the proportions and demonstrate how a crude bar of steel slowly evolves into a thing of beauty and deadly elegance.

I start by making a full-size drawing and tracing it on a piece of 8mm 56Si7 spring steel.

Next, the outline is cut out with an angle grinder. Then I set the edge thickness to 2mm, after final sanding it will be around 1mm. Since my heat treater is using salt baths, that's plenty thick enough. It's also no pleasure at all working on 58Rc hard steel so the closer to final shape before HT, the better. Naturally this leaves little room for error and corrections after HT (due to warping, sabering, etc) are difficult. It's all a trade off...

The next step is grinding in the distal taper. These types of longswords have a non-linear distal tapering that starts out convex and flattens out closer to the tip.

Finally, the blade is ready to have the actual cross section ground in. That's my favorite part of the entire angle grinding process as the sword now starts taking shape. Before it was just a graceless bar of metal, the shaping of the blade bevels changes that. It's also not as monotonous and stupefying as for example grinding in the distal taper.

And that's were we catch up to the original posts... Hope you enjoy it

---------------------------------

Hey guys

I figured since I'm currently working on a longsword but can't get anything done today (I HATE holidays where you're not allowed to make noise), I'd use my time instead to post some pics.

Because I'm busy with med school and spend most time at university, I rarely have to time to work on my projects so don't expect the sword to be done anytime soon... the last one took me a full year (with scabbard though).

Anyway, here we go. I only do stock removal on long blades (don't have a pass-through forge, just a wood-burning oven that luckily gets plenty hot enough for forging and heat treating small blades and axe heads).

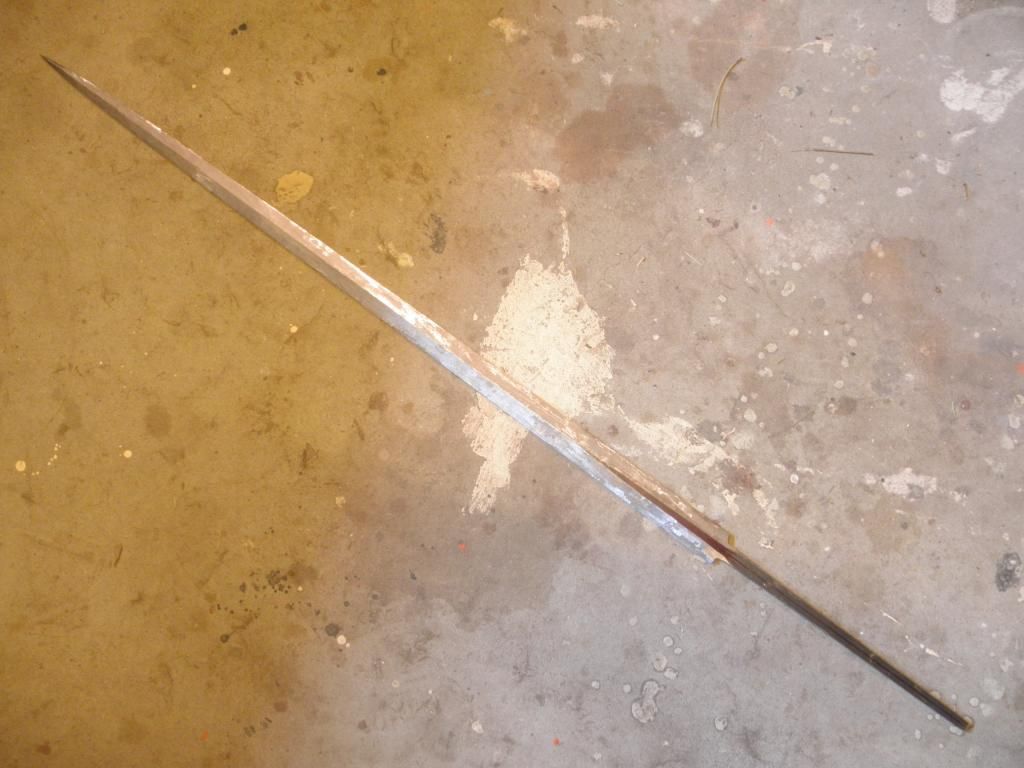

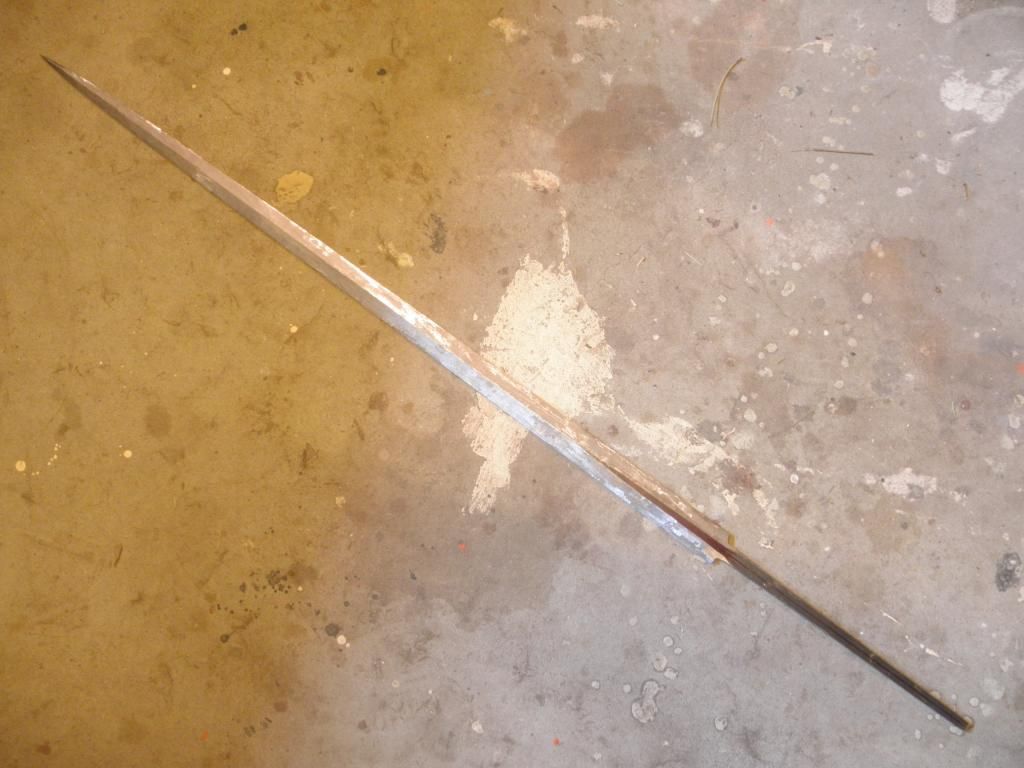

This is the blade after rough grinding with the angle grinder:

I started with 8mm stock and set the distal taper so that the finished blade would sport a convex distal taper to about 4mm before the tip. Overall length is around 133 cm btw, with the blade being about 100cm long. Classic 3:1 blade to handle proportions.

A couple hours at the belt sander (I found a 40$ one from ebay clamped into the vice works very nicely) and some draw filing at the tip later, I got this:

This is my set up for sanding btw (excuse the blurry photo, the light isn't too good in my workshop and nor is my camera)

I'm hoping to be able to continue working on the blade next week. I still have some small amounts of grinding to do, then it'll be onto hand sanding, my favorite part :? That should keep me busy till summer :lol:

I appreciate all comments! Thanks for looking...

I start by making a full-size drawing and tracing it on a piece of 8mm 56Si7 spring steel.

Next, the outline is cut out with an angle grinder. Then I set the edge thickness to 2mm, after final sanding it will be around 1mm. Since my heat treater is using salt baths, that's plenty thick enough. It's also no pleasure at all working on 58Rc hard steel so the closer to final shape before HT, the better. Naturally this leaves little room for error and corrections after HT (due to warping, sabering, etc) are difficult. It's all a trade off...

The next step is grinding in the distal taper. These types of longswords have a non-linear distal tapering that starts out convex and flattens out closer to the tip.

Finally, the blade is ready to have the actual cross section ground in. That's my favorite part of the entire angle grinding process as the sword now starts taking shape. Before it was just a graceless bar of metal, the shaping of the blade bevels changes that. It's also not as monotonous and stupefying as for example grinding in the distal taper.

And that's were we catch up to the original posts... Hope you enjoy it

---------------------------------

Hey guys

I figured since I'm currently working on a longsword but can't get anything done today (I HATE holidays where you're not allowed to make noise), I'd use my time instead to post some pics.

Because I'm busy with med school and spend most time at university, I rarely have to time to work on my projects so don't expect the sword to be done anytime soon... the last one took me a full year (with scabbard though).

Anyway, here we go. I only do stock removal on long blades (don't have a pass-through forge, just a wood-burning oven that luckily gets plenty hot enough for forging and heat treating small blades and axe heads).

This is the blade after rough grinding with the angle grinder:

I started with 8mm stock and set the distal taper so that the finished blade would sport a convex distal taper to about 4mm before the tip. Overall length is around 133 cm btw, with the blade being about 100cm long. Classic 3:1 blade to handle proportions.

A couple hours at the belt sander (I found a 40$ one from ebay clamped into the vice works very nicely) and some draw filing at the tip later, I got this:

This is my set up for sanding btw (excuse the blurry photo, the light isn't too good in my workshop and nor is my camera)

I'm hoping to be able to continue working on the blade next week. I still have some small amounts of grinding to do, then it'll be onto hand sanding, my favorite part :? That should keep me busy till summer :lol:

I appreciate all comments! Thanks for looking...

This is the sort of work I like to see, clean lines with smooth planes. Obviously done with the patience it takes to do good quality work.

This is the sort of work I like to see, clean lines with smooth planes. Obviously done with the patience it takes to do good quality work.

.

.