|

|

Post by Lukas MG (chenessfan) on Mar 19, 2017 23:00:33 GMT

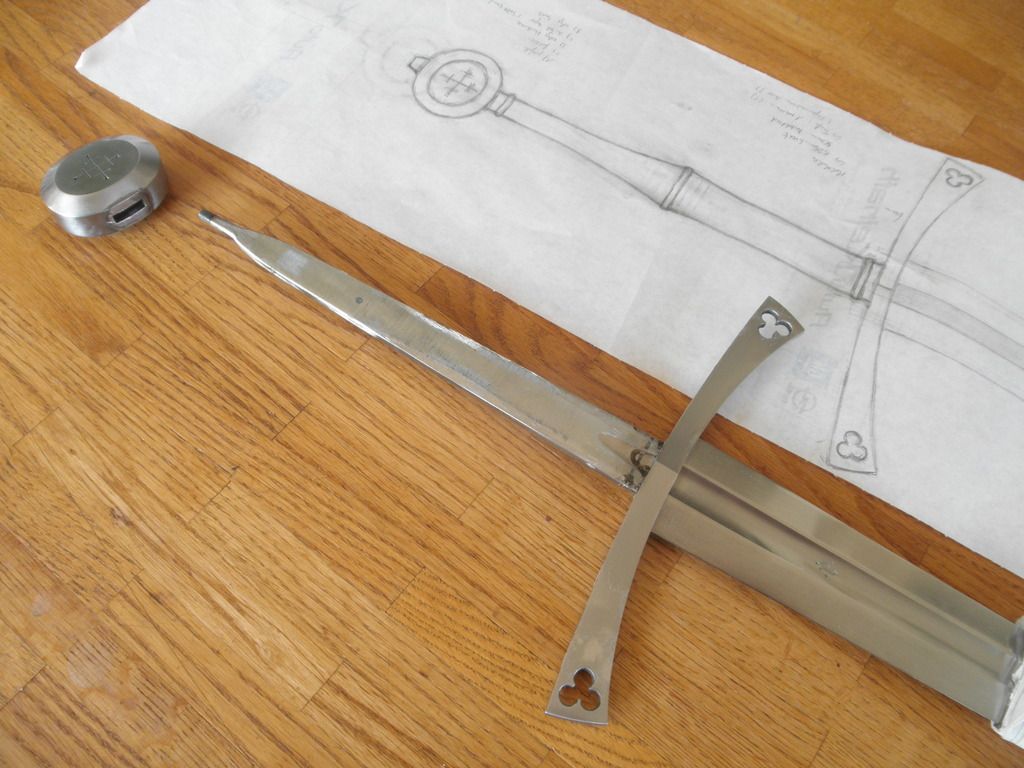

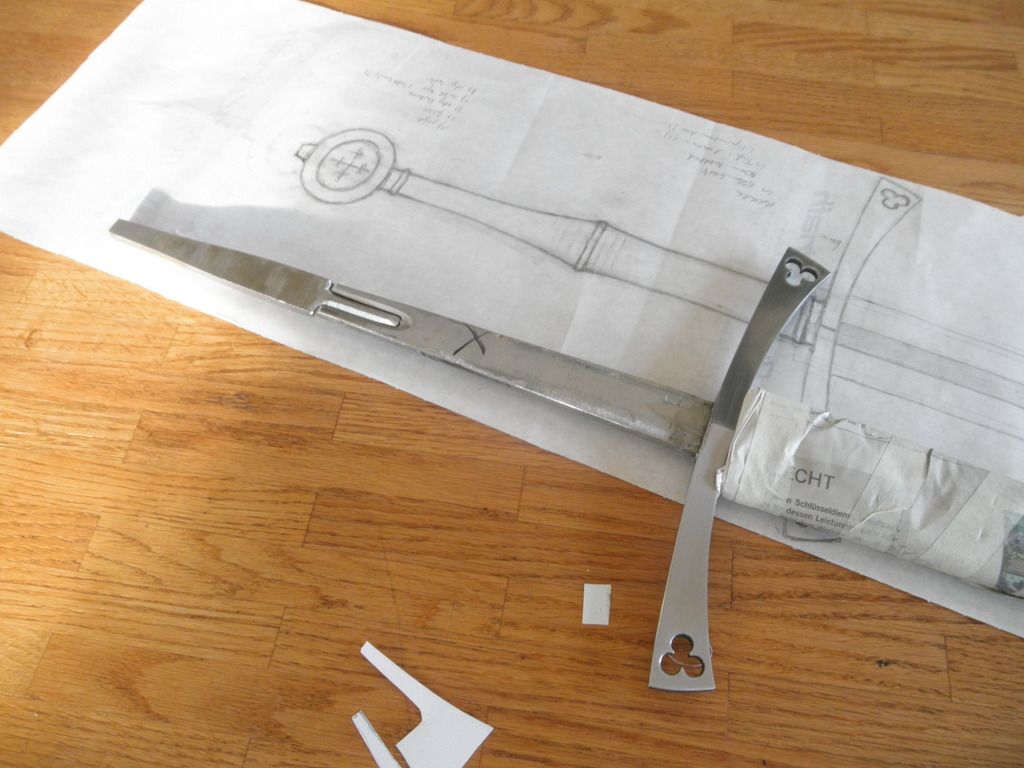

So I recently posted a review of the Albion Landgraf. You can find it here: sbg-sword-forum.forums.net/thread/50344/review-albion-landgrafAs you can read there, I am very impressed with the sword. It is the best allround longsword I‘ve used so far, combining a stiff thrusting blade with very good cutting potential. The one thing I could see improved was grip length. I just prefer the longer grips seen on late period longswords. I mulled over it for a while and then decided I would do something about it. I can never leave these things alone. So, here it goes: The sword taken apart. Yup, very solidly assembled, everything as it should be. Next to it you can see the full-size drawing I made to make sure my change would not mess up the proportions and aesthetics.  The extension is welded onto the tang. Done properly, with a deep dovetail and made from spring steel this should be perfectly sound. The most important aspect is the placement of the weld. It is in the mid section of the tang, far away from the stressed areas (blade shoulders and pommel section).  After welding and clean-up, the section was heated up to cherry red twice and allowed to cool slowly. This is to counter any potential grain growth from the welding. I whacked the tang onto a 2x4 several times afterwards to make sure everything is holding up. No issues. Here is the sword with the pommel again in place. I was prepared to re-grind the pommel as lengthening the tang (by 3cm in my case) does change the harmonics but as it turns out, the effect was solely positive and a re-grind was not necessary. More on that later.  And here it is with the grip mounted and cord wrapped. Leather is next but that will have to wait a bit.   Stay tuned and thanks for watching ;) |

|

|

|

Post by Bryan Heff on Mar 19, 2017 23:59:31 GMT

You're awesome man...I mean it. Too cool, I love it. Had I tried that I would have had to steal from the blade to lengthen the grip....but I would not have since I want the blade longer. The excellent weld solves all of that. Well done Lukas!

|

|

|

|

Post by Faldarin on Mar 20, 2017 0:17:22 GMT

As a proponent of longswords with longer grips, I absolutely love this. Thanks for sharing!

|

|

Ifrit

Member

More edgy than a double edge sword

Posts: 3,284

|

Post by Ifrit on Mar 20, 2017 1:20:19 GMT

Looks awesome! Fantastic job on the weld. Normally i dont care for welds but you did a really good job

|

|

|

|

Post by Jordan Williams on Mar 20, 2017 9:13:09 GMT

An amazing example of wonderful workmanship and a perfect example of a welded tang done right, with proper thought and care. I really like the longer grips on longswords, I think it looks very nice as well  |

|

|

|

Post by libra on Mar 20, 2017 17:09:41 GMT

That's one nice solution! Maximum contact surface. I read, that spring steels are not weldable, so at first I had some questionmarks over my head, but I assume you didn't do that without reason. Any more backgrounds would be appreciated, if you have the time (just a curious metalworker asking here  ). Did you weld yourself? Which welding process did you decide for? Very interested greetings  |

|

|

|

Post by Lukas MG (chenessfan) on Mar 20, 2017 22:07:23 GMT

That's one nice solution! Maximum contact surface. I read, that spring steels are not weldable, so at first I had some questionmarks over my head, but I assume you didn't do that without reason. Any more backgrounds would be appreciated, if you have the time (just a curious metalworker asking here :D ). Did you weld yourself? Which welding process did you decide for? Very interested greetings :) Spring steel can be welded (depending on alloy and carbon content). I wouldn't want to do it on a part that still needs to work like a spring because the steel can lose some of its properties (together with the heat treat) and the filler material can't match the original steel's springing quality. Re-welding broken car springs or the like is nothig but a hazard, a catastrophe waiting to happen. But for a tang at a section that isn't too stressed it's fine. The reason I used spring steel for the extension was that I wanted to have it at the pommel end where it is keyed. That is a stressed area and that part remained untouched by the welding process. As for the exact process, I used arc welding. It is important to anneal the welded area afterwards because the steel can really suffer from grain growth during welding. Pre-heating the area is also a good idea. |

|

|

|

Post by Lukas MG (chenessfan) on Mar 21, 2017 6:16:02 GMT

Oh and thanks you guys, I'm glad you like my modification.

@bryan: Indeed, welding opens a lot of doors for you...

|

|

|

|

Post by Robert on Mar 21, 2017 13:43:45 GMT

Looks quite nice, I like the waisted grip. What colour do you plan making the grip in?

|

|

pgandy

Moderator

Senior Forumite

Posts: 10,296

|

Post by pgandy on Mar 21, 2017 14:28:30 GMT

I like.

|

|

|

|

Post by Lukas MG (chenessfan) on Mar 21, 2017 19:29:54 GMT

Looks quite nice, I like the waisted grip. What colour do you plan making the grip in? Probably brown to match the scabbard. The suspension is dark green, that may be another option. |

|

|

|

Post by Robert on Mar 21, 2017 20:11:51 GMT

Wait, you got a scabbard for that beastie? SHOW PLZ

Also IMHO it looks nice if the grip&suspension is the same colour, while the scabbard itself is sllightly different.

Also my Sempach is still stuck with customs ;__; Never again shipping to Poland.

|

|

|

|

Post by Lukas MG (chenessfan) on Mar 22, 2017 11:06:39 GMT

I'll post a pic of the entire set-up once it's done ;)

|

|

|

|

Post by Faldarin on Mar 22, 2017 23:12:50 GMT

Please do. I'm clearly not drooling enough yet.  |

|

|

|

Post by seriouslee on Mar 22, 2017 23:30:04 GMT

Wow. Really well done.

|

|

|

|

Post by Madmartigen on Mar 23, 2017 9:57:07 GMT

I love it! Great job, and really nice proportions after your remake.

Looking forward to see the complete pics.

|

|

|

|

Post by Adrian Jordan on Mar 26, 2017 2:58:28 GMT

Dude, gorgeous.

|

|

|

|

Post by Jussi Ekholm on Mar 26, 2017 8:53:39 GMT

Very interesting Lukas. Would be nice to try out the original and this modified.  I am wondering how this will change proportions of the sword in sense of the circles, trianges, squares etc. geometric theories that Peter Johnsson is focusing on? |

|

|

|

Post by Lukas MG (chenessfan) on Mar 26, 2017 17:49:15 GMT

I don't know what the underlying geometric plan for the original Landgraf was, possibly it doesn't have a specific one (I'm not sure if Peter was working with these theories back when he designed the sword for Albion). The new version is of pretty typical longsword proportions with the blade/hilt ratio being (almost) 3:1 and the grip being the length of the guard (well, 1cm longer but close enough).

|

|

|

|

Post by Lukas MG (chenessfan) on Mar 29, 2017 19:03:01 GMT

Custom Albion Landgraf The tuned Landgraf is finished. I went with a dark green leather wrap to match the scabbard‘s suspension. It‘s always tricky to match an already dyed leather in color but it‘s close enough I think. The scabbard was made by Bryan Heff from SBG. The fit of the sword is excellent, it fits firmly and securely yet can be drawn very comfortably. I can certainly recommend his work. Onto the sword... The most interesting aspect of course is how the lengthening of the tang has affected the sword‘s proportions and harmonic balance. I do not know if there was an underlying geometric base for the sword. I did a good bit playing around with various tang lengths to see what works best with the overall proportions. The end result is a sword of pretty typical longsword proportions. The blade to hilt ratio is 3:1, the guard (almost) the length of the grip. A longer handle would have called for a new (wider) guard but I wanted to get this done without too much work and undoubtably, I would also have had to re-grind the pommel in that case. I was prepared to re-grind the pommel even so but as it turned out, that was not necessary. With the longer handle, the forward pivot point moved to the very tip of the sword but not past it so it is now exactly where I want it to be. The handle node didn‘t move much, it‘s located shortly before the middle riser, when gripping it lies beneath the ring finger. Also exactly where it should be. Overall, the handling did change noticeably. The basic characteristics are the same but to me, it feels more „refined“. Point control and blade movements feel crisper, more natural. Undoubtably there is a large portion of personal preference in this as I really am used to long-handled longswords. All being said, I am very happy with the outcome and very glad that I decided to do this (I had a moment of doubt or two along the way...). I hope you like the „new“ Landgraf as much as I do! Cheers, Lukas       |

|