Mikeeman

Member

Small Business Operator

Posts: 2,904

|

Post by Mikeeman on Apr 20, 2015 20:12:04 GMT

Thatza somea nice looking tillera! For whatever reason, I read this in Mario's voice.  |

|

|

|

Post by ineffableone on Apr 21, 2015 0:12:33 GMT

Got a little bit more done on the bow. Glued up the last lamination, the 3 piece part that goes between the helper and main bow.

Sanded down the ends of the laminations that had finished being glued, so they are ready to meet up with the bow and get glued to it. It helps to sand the angle now since once glued to the bow you have to be careful of cutting into the grain of the bow.So getting nice tapered ends now saves a lot of stress latter.

I also cut the 4 limb nock overlays. I will likely be gluing the limb nock overlays and the handle laminations to the helper bow tomorrow. Started reducing the poundage and scraping the ends down so the ends weren't overly thick and stiff. Started this with it unstrung so I could access the nock areas easier.

I then noticed that the limbs had a bit of twist to them when I did string it up to exercise the bow limbs. From the top or back of the bow

From the belly looking at the tips of the bow down the length.

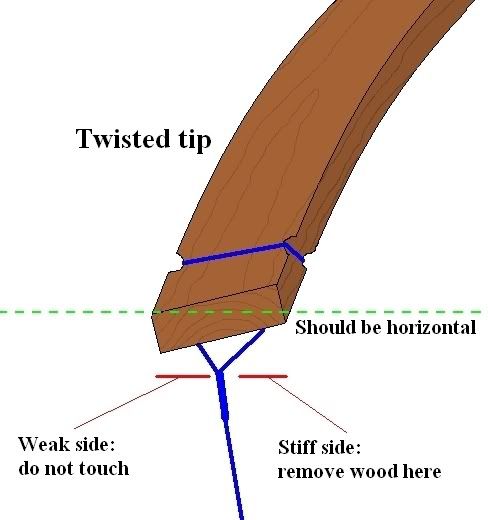

To solve this you have to scrape only the stiff side. I found this picture from paleoplanet that helps illustrate the concept  So I pencil marked the areas where I needed the most work and scraped away.

I have gotten the bow a lot less twisted, however I am down to 42# now, and don't want to get below 40# or if I have to only barely below 40#. So I have stopped so I can come back fresh rather than trying to get the last bit at the end of my stamina. One limb now has almost no noticeable twist, while the other still has a small amount that is still slightly noticeable. Tomorrow I will work on getting that twist out and hopefully stay at my wished for 40# draw weight. Until I get the twist fixed, I wont be gluing any overlays or handle laminations to the main bow. The helper bow however I can glue tomorrow so that I have as much ready as I can for when the main bow is ready. Hopefully I can get the twist out tomorrow and at least glue the overlays on to the main bow. |

|

|

|

Post by ineffableone on Apr 22, 2015 23:00:38 GMT

Today's update Got the helper bow Zebrawood and Wenge laminations for the handle riser and nock overlays glued on.

Also did a bunch of scraping to try and correct the limb twist. And while I got some twist out, I was noticing that the profile for the limbs was starting to get less and less even. Not overly so as I stopped before it got too noticeable. This is telling me the twist is not due to me removing material unevenly but that there is a natural twist to the limbs. So instead of making the bow limbs an uneven profile I am planning to use a heat gun to help remove the twist. I will clamp a weight to the side I want to correct and then heat the limb to bend out the twist. Similar to this video from BoarriorBows shows, though my limbs are not nearly as twisted as the ones he is fixing so it should be much easier for mine. Rather than setting up the untwisting today, I am going to wait till tomorrow or when I have good chunk of time to really monitor the process. Last thing I want to do is over twist it. Since I don't plan on much more removal of limb material, I started the long sanding process on the main bow limbs. |

|

|

|

Post by ineffableone on Apr 25, 2015 4:39:14 GMT

So my brother had loaned out his heat gun, and I just got it tonight. So will likely be attempting the twist correction over the weekend. Not a whole lot to note or take pictures of the past couple days due to this. A lot of sanding of the limbs starting with 100 grit, then 220, then 400. Since I couldn't proceed with the rest of the bow build sanding was at least something I could knock out a bit of so I wasn't loosing too much time. I also sanded out the helper bow's nock overlays string grooves. Which was the most exciting and interesting part of what I did get to do and only thing worth some pictures.

|

|

|

|

Post by ineffableone on Apr 25, 2015 23:29:03 GMT

The untwisting was minimal so it went fairly quick. Set up and waiting for it to cool down took longer than the actual untwisting. It didn't show up in the pictures but I used cooking oil to protect the wood from the heat gun. You can see the bottle of Crisco oil in the background of some of the other pictures.

Adding weight (tape measures) to a small bucket to give the wrench leverage to untwist the limb

Checking the end to make sure I don't over compensate

While I was at it, I gave the limbs a bit less curve from the tillering process by heating up the sections then clamping down to thew bench.

Next was gluing. I glued the nock overlays to the main bow.

And the handle section

Tomorrow I can shape the nock overlays and glue the helper bow to the main bow. Sadly due to the limb twist I wont be getting this bow done till sometime next week. But things are moving forward and I am looking forward to getting the parts put together so I can get the shelf cut out. From there is is just sanding and finishing the bow. |

|

|

|

Post by chrisperoni on Apr 26, 2015 0:41:41 GMT

Coming along nicely indeed

|

|

|

|

Post by ineffableone on Apr 28, 2015 0:14:59 GMT

Some good progress today. Got the main bow nock overlays sanded down and shaped. Bottom main bow nock

Upper main bow limb nock with stringer groove.

Sanded the handle sections of the main bow and the lamination on the bottom of the helper bow to make sure there was a nice flat even surface to glue together.

Then it was time to glue the helper bow to the main bow. Making sure to line up the center lines

Starting to look like a Penobscot bow now that the helper bow is attached to the main bow.

Tomorrow I can work on cutting out the shelf and sight window, shape and sand the handle section, and finish sanding the bow limbs and string nocks. At that point it will be ready to test fire. Then time to do the finishing which will actually take a couple days for the several linseed oil finish coats to soak in and dry, then topped off with a wax coat. Once the finish is soaked in nice and dried I can then place the beaver fur arrow rest and plate, string up with the fast flight string which will replace the dacron string, put some llama wool string silencers in the string, and add the brass nock point collar. My estimate is full finish will be by next weekend. But tomorrow should be the essentially finished point. With all the shaping and hard work done. Of course this is where I had the catastrophe last time, so I will be taking my time and being careful while shaping the handle to make sure there is plenty of material to support the bow. And of course not drawing the bow without the helper bow strung up also. That was the critical mistake last time, drawing the main bow without the helper bow strung up. |

|

|

|

Post by aussie-rabbit on Apr 28, 2015 9:20:35 GMT

Not wanting to distract this thread,  has there been a bow with 4 limbs that are in the form of a H ? such that the centre is the exit for the arrow ? |

|

|

|

Post by ineffableone on Apr 28, 2015 18:29:31 GMT

Not wanting to distract this thread,  has there been a bow with 4 limbs that are in the form of a H ? such that the centre is the exit for the arrow ? Yes quite a few have tried that design. A lot of people tried it as a way to get over the archer's paradox of having to bend the arrow around the riser. However it means you need to either use a pinch draw, or mechanical release since the Mediterranean or Mongolian Thumb draw naturally adds torque to the arrow. The H style bows never caught on. There have been quite a few that have been tried from about the 60s to the 90s but none have gotten much notice and most have faded away quietly. It is a lot of extra weight and bulk to add to fix a problem that really isn't much of a problem. |

|

|

|

Post by Timo Nieminen on Apr 28, 2015 20:01:02 GMT

They're relatively slow bows. If you double-up by having two bows side-by-side, you get double the draw weight and double the weight in the limbs. That is, the doubling of the draw weight gives you no improvement in speed (if you keep the same gpp for the arrow). Double the draw weight the usual way, by making the bow thicker, and you only increase the weight of the limbs by a little bit (by about 25-30%)

|

|

|

|

Post by ineffableone on Apr 29, 2015 1:25:48 GMT

OK so the good and the bad. Good news, don't worry it didn't break. Bad news, I made some dumb mistakes being too excited to get this finished and didn't wake up enough and pay attention enough to catch these dumb mistakes. So the bow is not as cool as I would have liked, and I will eventually be making another one. LOL. But for now this one will have to do, I don't want to spend another month making another bow. Ok so now to my mistake. When cutting out the handle and shelf I did something wrong. I cut the shelf into the back of the bow instead of the side. I also cut the shelf so what was supposed to be the upper limb is now the bottom limb, not the biggest deal and only thing that effects is the stringer groove is on the bottom limb instead of the top one like it should be. *sigh* Oh well, it didn't hurt the bow, other than making it look a bit odd.  So rather than get upset, or scrap the project, I kept on and shaped the handle. Close up of my mistake after handle shaping.

Riser detail

I found I needed to cut some string grooves in the main bow's nock overlays for the helper bow's strings to ride in.   I have been able to put 3 coats of boiled linseed oil on and after I post this I will go add another coat. While the Penobscot bow didn't quite turn out like I wanted due to my own error. It is still cool, and it still shoots nice. Once the bow soaks up plenty of linseed oil, I will give the bow a nice wax coat to seal the oil in. Then start adding the finishing touches. Beaver fur arrow rest and plate, fast flight string, llama wool string silencers, and brass nock point collar. Penobscot bow build, almost finished |

|

|

|

Post by chrisperoni on Apr 29, 2015 3:43:20 GMT

Riser shape is all up to you and no one would have known if you didn't tell us the back cuts weren't om purpose. I really like the shape and everything overall. Can't wait to see it finished and maybe a video?

|

|

|

|

Post by ineffableone on Apr 29, 2015 4:14:20 GMT

Riser shape is all up to you and no one would have known if you didn't tell us the back cuts weren't om purpose. I really like the shape and everything overall. Can't wait to see it finished and maybe a video? I don't have a video camera that I can use, my phone's video is beyond horrendous or I would just use that.. But I will post plenty of pictures when it is done. |

|

|

|

Post by ineffableone on Apr 29, 2015 22:14:35 GMT

Ok the Penobscot style bow is now pretty much finished. Just adding the beaver fur arrow rest and strike plate Added the fast flight string, and a brass nock point collar. As well as some teflon tape to the nock point. I do this due to fast flight strings being thinner and it makes nocking easier due to quick visual of where the nock point is. Plus teflon tape is very slick so it also adds to easy of the arrow nock coming free of the string with less friction.

Added some llama wool string silencers. This time I got black wool (luck of the draw) last time for my Samick Sage they sent me light brown and white. Amazing the sound difference from no silencers to these. Super quite. Oh and cuddly silky soft too.

Am I hearing swearing and frustration at me showing pictures of just parts, rather than the whole bow? Are people saying "ya ya just get to some good shots of the bow, we have been waiting to see the thing this entire build thread." Ok time to show ya my new Penobscot bow

And I got to do some shooting of my Penobscot bow Just tossing a few arrows into the target to get used to it Going for a bit more accuracy with the Penobscot bow I know your saying hey what about that one off to the right. Look a bit closer, notice the missing fletching? Yep on release the fletching fell off. This was an older arrow, and had already had a chuck taken out from another arrow hitting it. This is part of why I usually only shoot one arrow at a time, instead of doing groupings. You damage more arrows shooting groups.  Over all I am pretty happy with this Penoscot bow. Yes eventually I will make a new one, without messing up and putting a shelf on the front. However right now, this one is working fine, and will likely last me years. So no hurry to make a new one. Plus taking my time with this one will let me get more ideas for the next one. Gain some experience with this style and figure out some possible extra features to add to it to improve the performance. Not sure if I will go with the Rudder Bows kit next time, or make one from scratch. I am sort of leaning toward making one from scratch. However that is no knock on Rudder Bows Penobscot kit. The kit is great, and makes it easy to build one of these. However if I make a new one I might want to change some things up that I would not be able to do with the kit. We will see, for now I am having fun with this Penobscot bow, and hope everyone enjoyed following along with the build on the thread.

|

|

|

|

Post by bigpete on May 18, 2015 8:57:22 GMT

Is it still holding up ok ?

|

|

|

|

Post by ineffableone on May 18, 2015 9:07:07 GMT

Is it still holding up ok ? Yep still going good, had it out in the back yard doing some shooting the last couple days. I am really enjoying it. With the llama wool string silencers it is nice and quiet too. |

|

|

|

Post by bigpete on May 18, 2015 9:13:52 GMT

Cool. I'm finally calling it quits with my Wytchstyk and dropping bow weight soon, going to get myself a martin savannah in 55#, at my draw it will be 65# and will eclipse the arrow speed of my existing bow. Old age sucks ! Still have plenty of strength but my joints don't like it anymore so why fight fate LOL :) Are you going to hunt with the Penobscott ?

|

|

|

|

Post by ineffableone on May 18, 2015 11:18:54 GMT

Cool. I'm finally calling it quits with my Wytchstyk and dropping bow weight soon, going to get myself a martin savannah in 55#, at my draw it will be 65# and will eclipse the arrow speed of my existing bow. Old age sucks ! Still have plenty of strength but my joints don't like it anymore so why fight fate LOL  Are you going to hunt with the Penobscott ? My Samick Sage is my hunting bow, for the obvious reasons of it being a no tools take down making it easier to pack into the field. However at some point I would like to take the Penobscot bow out hunting. |

|

|

|

Post by Derzis on Mar 21, 2016 18:33:19 GMT

Very nice bow and nice recover from the breakage.

|

|

|

|

Post by ineffableone on Jun 26, 2024 21:08:43 GMT

Yes I still have it, and it works great!

|

|