|

|

Post by Svadilfari on Apr 3, 2012 21:46:00 GMT

I'm pretty much a confirmed Euro man (or at least I thought I was) but the more I look at japanese blades the more I waver . Looking at the many, many ( almost infinite) examples of todays blades set me to wondering. With regards tsuba, I know there are an awful lot available..but to be usable. they must fit the blade. Are most of today's blades made to a "standard size" ?? I can't see tsuba makers making half a dozen or more sizes, just to fit different blades, or do the ? assemblers? file out the tsuba to fit the blade at hand ? And what is the correct fit between Tsuba and blade..should it be a sliding fit..or a tight friction fit ? Obviously it shouldn't rattle about..but how tightly should they fit..should they move with simple hand pressure..or should they move with some..encouragement ?

Thats for todays swords. Now a question about the Past. Were Tsuba's in the past custom fitted to each blade ? By that I mean, if a samurai desired to change his sword's fittings..would he be likely to be able to get one "off the shelf"..or would he have to chose one, and then have it custom fitted to mount on his blade ?

|

|

|

|

Post by chopper on Apr 3, 2012 22:01:49 GMT

I would say that today's tsubas are cast in quantity from molds. Usually molded from antique tsubas from museum and personal collections. They would have to be fitted to each individual blade becasue no two blades are going to be exactly alike, even if they are made for mass produced production swords. And the fittings should be tight with no play at all.

In the past there would be different people skilled in different aspects of sword making. They blade would be made by the swordsmith, It would then be handed down to the polisher to polish the blade. Then it would be sent to another person to make the fittings and so on and so on. If the Samurai would want to change the fittings, he would more than likely have them commissioned and then fitted to the blade. Im not 100% certain but I doubt they were mass produced.

If I remember correcty, some designs on the fittings were could be clan or family oriented.

|

|

|

|

Post by Student of Sword on Apr 3, 2012 22:38:14 GMT

In the past, some fittings were made specifically for a sword. But most weren't. Tsuba are made by people who specifically made tsuba and they made them without regard to the swords, because they would not not which sword will be fitted to. However, tsuba had a copper liner at to and bottom of the the hole. A mounter can easily adjust the tsuba to fit the sword.

|

|

|

|

Post by Lobster Hunter on Apr 3, 2012 23:01:08 GMT

I've noticed that the nakago hole in most modern tsubas tend to be a bit on the small side, necessitating some filing. If the hole is too big, a shim made out of a softer metal like copper or brass works pretty good. As long as the fit is snug enough to prevent lateral movement once the sword is assembled, it's all good.

|

|

|

|

Post by Lee Bray on Apr 4, 2012 4:32:57 GMT

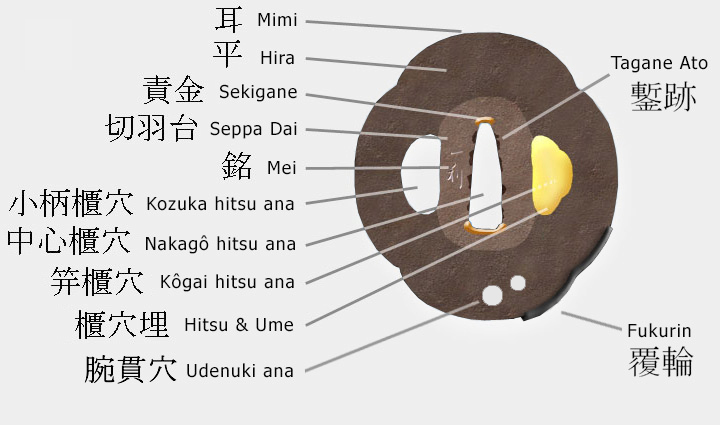

Good tsuba, past or present, are not cast as cast steel tends to be brittle. A modern cast tsuba that I tapped with a hammer as a test - Casting makes for very large grain in the steel which makes it brittle and of little use as a tsuba. But it's cheap and vendors need their profits. Good tsuba will be made from plate steel and the best tsuba(in terms of craftsmanship) will be forged from traditionally made steels. There are plenty of modern makers(tsubashi) from Japan to the States, South Africa, Italy and even little old me here in Hong Kong. Fitting a tsuba to a new blade was common practice in the past. Sekigane are used, which are two pieces of copper shim(though I've seen lead and silver used) fitted into the tsuba ana at the mune and ha. These provide an easy to fit soft metal junction between sword steel and tsuba steel, which created less wear and tear. Attachments:

|

|

|

|

Post by Jakeonthekob on Apr 4, 2012 19:56:47 GMT

In the past only those with lots of money could commission custom fittings for their blades, etc. Nowadays, you won't get that on production blades. However, some contemporary sword smiths and other modern artisans do custom make and fit koshirae for that one particular blade.

For example, I'm having a swordsmith custom forge and mount a katana. This means that the wood components such as the handle and sheath are carved to fit that blade exclusively. Also the metal fittings such as the tsuba, fuchi, kashira, and habaki (blade sleeve) are custom fitted to the blade as well, therefore there will be little to no play at all from any of those fittings and will ensure perfect fit.

|

|

SanMarc

Senior Forumite

Posts: 3,193

|

Post by SanMarc on Apr 6, 2012 6:50:01 GMT

Yep, thats why mine are made from plate steel.....

Iron if I can get it.

....................SanMarc.

|

|

|

|

Post by ineffableone on Apr 6, 2012 7:44:05 GMT

Some nice pictures to help explain    of course one of the most popularly seen fitting techniques is seen in this  Notice the dimples, they are done to fit the tsuba to the sword. You will even see modern reproduction tusba that still have these imprints from the original's mold. These are done by hammering a punch in soft metal tusba to get the metal to spread and tighten up on the nakago. This I think is by far the most common method of tightening a tusba you will see. Though others are correct. If you had a tsuba of harder metal you can't do this, so instead inserted softer metal into the the necessary parts of the nakago ana. It was quite common to actually keep old hardware and have it fitted to a new sword. Especially the older stuff as it usually out lived the sword. Swords tend to break and get damaged when used regularly. Many tsuba were passed down through generations while the swords themselves were broken. There is also some evidence that in early times tsuba were replaced with leather tsuba for war. To ensure the tsuba would not be lost and stay in the family. However there is little surviving antique leather tsuba as they were not preserved and generally discarded after use. So filling gaps etc was quite a common experience to have to fit an old tsuba to a new sword this was not just recycling old fittings but holding parts of their ancestors in their swords keeping a connection like that was important. Though as Jakeonthekob mentioned a sword could have a tsuba custom made for it, historically though it usually was not by the smith himself but a craftsman who specialised only in the fittings, just like there was a craftsman who only did the polish. |

|

|

|

Post by Lee Bray on Apr 6, 2012 14:20:49 GMT

A couple of clarifications, respectfully.

It's possible to use punches on steel/iron tsuba for the purpose of fitting.

A punch is made from hardened steel and tsuba(refering to antique Japanese tsuba), in my own opinion, were probably made of softer steel/iron, or at least unhardened.

The mild steel and wrought that I've made tsuba from have been easy enough to peen with punches I made and hardened myself.

I'm not sure that leather 'replaced' anything but was actually used for the purpose as it was cheaper than steel and kinko tsuba. Lacquered leather made for a solid tsuba, though not as strong as steel or kinko tsuba, and there are varying school of thought on the reason for tsuba being to stop a sword strike or to prevent the users hands slipping onto the blade, so perhaps ultimate strength is not an issue. As steel became more available, perhaps leather was deemed unsuitable. And leather does not last as well as metal (modern Chinese stainless notwithstanding) so there is good reason why few have survived. They are still around though - a nice leather Momoyama period tachi tsuba sold on a Nihonto classifieds for $400 recently.

|

|

|

|

Post by Svadilfari on Apr 6, 2012 21:45:26 GMT

Thanks for all the useful info, Folks. Most helpful  |

|