|

|

Post by Jayhawk on Sept 5, 2014 2:42:06 GMT

The OP's name is clearly Eric :roll: , but I am remiss in providing an update since I sharpened the sword. I've cut branches, milk bottles, 2 liter coke bottles - all with no problems. Sword still straight, no issues with the hilt. I tell you...it's a nicely made sword...great value for the price. Is it perfectly made - no, but it is perfectly functional despite being less than perfect.

And honestly, I think we expect more of our modern swords than is historically accurate. I've got about a dozen antique swords and daggers...and the tang on this sword is thicker than all but one of them (an early 20th century Spanish saber).

Eric

|

|

|

|

Post by aussie-rabbit on Sept 5, 2014 2:55:37 GMT

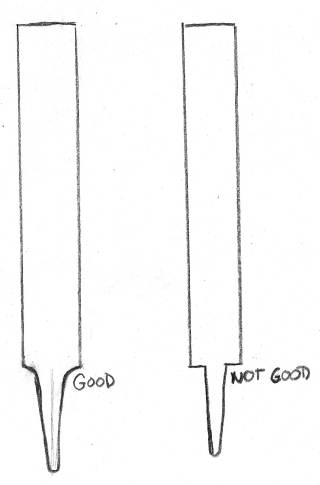

That is the critical area, the shoulders where the tang is formed from the blade need to be rounded like this somewhat exaggerated example -  Overall looks like reasonable value but not an "everyday cutter"  |

|

|

|

Post by Jayhawk on Sept 5, 2014 3:02:16 GMT

I'm not taking it apart again since I gorilla glued on the cheap end cap and don't want to rip it apart, but it was much closer to your good picture than the not good picture.

I've cut with it frequently...it's a good everyday cutter. In fact, comparing it to my Philippines bolo my uncle brought back from when he served in the Vietnam war, and which he and I both have essentially used as our camping ax and cut a ton of wood with for fires...it's tang is much, much beefier and better made.

Eric

|

|

|

|

Post by aussie-rabbit on Sept 5, 2014 3:09:54 GMT

Sounds positive, even a small curve is enough to minimize the problem, I have to say I'm not a fan of welded threads but at least yours looks like a good arc weld rather than the rat-tail "spot-weld" - happy swinging :lol:

|

|

|

|

Post by Jayhawk on Sept 5, 2014 3:15:29 GMT

The weld is very good...it really annoyed me at first, but I fully trust the blade and tang now. I may have shipped it back to Sword n' Armory if I hadn't read that article about TInker swords and such welds being OK if done right. Plus, the weld is further down on the tang behind where your hand sits on the hilt, so I think that minimizes any stress on the weld point.

|

|

|

|

Post by AlvaroWang on Sept 5, 2014 4:21:21 GMT

Sorry for that Eric, I was so interested in the content of your review that I missed you name  Apologies |

|

|

|

Post by Jayhawk on Sept 5, 2014 10:41:29 GMT

No problem! I was actually joking...but that doesn't always come across well on a forum.

Eric

|

|

|

|

Post by Jayhawk on Oct 13, 2014 3:43:29 GMT

One more update...the dao was used by my son today to cut pumpkins (the heavy pie type, not the carving type) that were thrown at his head. He was demonstrating sword techniques with his fencing class, and the pumkins (5-10 lbs each) were thrown from about 10 feet away and he split several with the dao and using a point thrust speared one on the end of the dao. Sword functioned flawlessly.

|

|

|

|

Post by AlvaroWang on Oct 20, 2014 23:49:58 GMT

OMG…

Cutting pumpkins thrown at you is not what I think when I think light cutting… It is sturdier than I realized

|

|

|

|

Post by Jayhawk on Oct 21, 2014 0:57:43 GMT

Yep...it's one tough sword. My son's fencing master, who does both sport and historical weapons (long sword, real sabre, rapier, etc.) was impressed by it. He's not a Chinese sword expert and will tell you so, but he knows a good blade and really liked it. The rest of the fencing school used Hanwei long swords, an original Patten model sabre, and my son also used a Deepka arming sword (general consensus was it was functional, but just barely) and a Hanwei viking axe which everyone really enjoyed splitting thrown pumpkins with. It was remarkably fun to watch and for my son.

|

|

|

|

Post by aussie-rabbit on Oct 21, 2014 2:25:54 GMT

Years ago we used Paddy melons ( a weed in Australia) as targets.  |

|

|

|

Post by Suho on Oct 22, 2014 10:24:44 GMT

Throwing pumpkings seems like a good workout in itself, but definitely sounds like fun! Right now, my son (4 years old) is still in the phase where he gives our little Halloween pumpkins names (this year's is "a girl pumpkin" apparently, and her name is "A Nice Pumpkin.") When he was younger there was "Mr. Pumpkin" or "Pumpkinhead" and I forget what last year's was. They have to mysteriously disappear in the night sometime after the holiday with the explanation being that they have gone back to their family. I'll admit I get a kick out of it and he's almost too old for this but he's growing up so fast as it is.

I doubt he'd be too thrilled if I chopped his pumpkin, but on the flip side, he is going to be a Ninja turtle for Halloween this year so I think he might be more interested in the sword if I did decided to chop it. [Of course, I'm going to put on some "medieval" type clothes and carry a sword, too, to bring him out trick-or-treating.]

|

|

|

|

Post by Robnose on Apr 18, 2015 17:07:30 GMT

Just got mine this morning. It's a very nice piece for the price point. Spent the morning fixing some issues:

-rounded the tang shoulders.

-shimmed and epoxied the habaki/collar.

-epoxied the tsuba/guard.

-shimmed and filled the void inside the handle with epoxy and attached it.

It will take 3-4 days for the industrial epoxy to cure but the sword is solid as a rock. Everything is lined up and fitted together perfectly. It's a beautiful piece and the DIY work was a nice way to relax...

|

|

|

|

Post by aussie-rabbit on Apr 19, 2015 3:09:06 GMT

Also from the photographs the tang meets the blade forming a 90 degree corner, this should be a radius like the Morigan blade otherwise you end up with a stress point where the blade and tang meet, a bad cut even on light material can see this area fail giving you the "helicopter of death" so please be careful.  |

|

|

|

Post by Robnose on Apr 19, 2015 12:59:35 GMT

When I disassembled mine, I noticed there is enough "meat" around the collar and guard to totally reshape the tang shoulders. You would lose a couple inches of blade length but could properly shape the tang and even eliminate the threaded end. My biggest concern was that the tang passed through the handle via a 1/2"-5/8" round hole. No wood to tang contact at all. I filled the void with half round wooden shims and epoxied it all together. After I rounded the tang shoulders of course.

|

|

|

|

Post by Jayhawk on Apr 19, 2015 17:17:04 GMT

Aussie-rabbit - the photos are not the best, because it's not a true 90 degree angle...it's rounded in the angle-ish bit if that makes sense. Rubnose's sword had a few more issues than mine (definitely need to glue/epoxy the ornamental bits), but the blade and tang are rock solid. Heat treatment seems good...my son's historic fencing master, who owns a ton of blades and uses them in blade to blade combat, felt the sword was rock solid as well. Pumpkin cutting is much more of a test than anything else I can think of...especially pumpkins being thrown at you from 10 feet.

Eric

|

|

|

|

Post by Robnose on Aug 6, 2015 21:33:04 GMT

well, my dao came apart after a few smacks on my chopping block. The handle and fittings came loose but the blade held up like a trooper. any suggestions for the blade modifications?

|

|

|

|

Post by Timo Nieminen on Aug 6, 2015 22:16:42 GMT

What broke? Threaded end of tang broke off, or just loosened/stripped the nut?

Either way, might be a good candidate for remounting with a peened pommel.

|

|

|

|

Post by Jayhawk on Aug 7, 2015 18:58:24 GMT

Is it all just loose or as Timo mentioned are the threads stripped? If the threads are still good and the issue is the hilt doesn't snuggly fit the tang (mine form fits really well), you can epoxy inside the hilt to firm it up or alternately shim it with something (I have used bamboo skewers before). If it is just that the nut comes loose frequently, a drop or two if blue locktyte from the auto shop will take care of that. A picture might help, too.

Edit - just re-read your earlier post about epoxying thr hilt with hald wooden rods to fill the gap. Do you just need to make a new wooden hilt that actuall fits correctly? You could peen it as per Timo, but if the threads are good it could be an interesting project to turn the hilt yourself. I have a few swords with just a washer and nut to hold it all together, and unless the wooden hilt fits well, they are problematic but work fine with a snuggly fitting hilt.

|

|

|

|

Post by Jayhawk on Mar 4, 2016 21:53:48 GMT

I dont know that its even 1045 just because they say its medium carbon steel. 1045 is the lowest carbon content on the spectrum of HIGH carbon steels i believe thats because of the fact that anything lower carbon content would not be able to be sufficiently hardened and technically because it has a rat tail it is not able to be classified as a battle ready sword. I only say this to warn you, the last thing you want is that heavy blade turning into a helicopter crash Ummm...that's kind of you to worry, but did you read the thread from the start? Read the Tinker article on welded on threads? Read that the consensus from professionals who have trained at the US Olympic center for sport fencing, and who also teach historical fencing, feel it's a great blade? There is no question it's at least 1045...no idea if it's 1055, but it's good steel. Holds it's edge wonderfully despite aggressive cutting. The fittings are the only real issue, and the hilt can apparently be hit or miss on how well it's cut to actually fit the tang (mine is pretty good). For the price it's great and it's issues fixable. I know what the description says, but unless they've changed who they are sourcing it from...it's safe to cut with and the best dao for the price out there. Eric |

|