Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 6, 2009 14:28:27 GMT

I've considered adding a modern flair to my collection by adding one or two of the WeaponEdge guntos; I've found out they're 1050 steel. My original desire was to sharpen them so I could do a full review complete with cutting vids. What are your experiences with 1050?

M.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 6, 2009 15:41:11 GMT

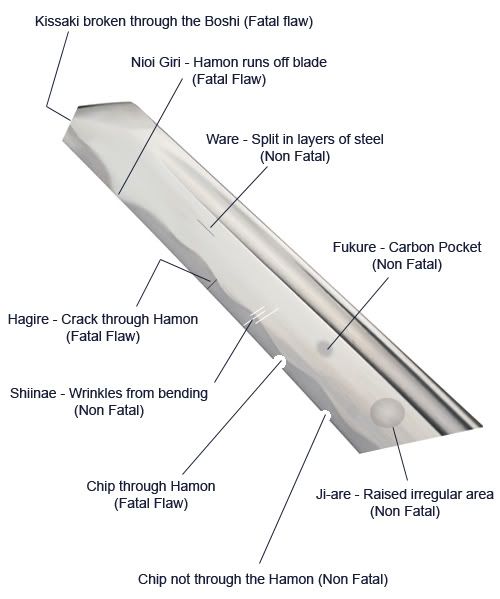

I have a sword made from 1045 steel,and one made from 1060. they are both good entry level swords. CS uses 1055 steel and you might have seen their proof vids on you tube. The thing you want to know, more than the sword being 1050 steel, which is not the best monosteel, but certainly not the worst, is how was the sword made/ heat treated, etc. You can have the best steel known to man, and it being forged by an inexperienced smith, or even a good smith who doesn't really care, and still have a blade that is not worth hanging on your wall for Halloween. There is a matter of how the smith forges the blade to align the carbon atoms (grain if you will), and then there is the hardening and tempering process. Then, depending upon your preference, and sword style, is it through hardened, or differentially hardened? There are even katana that are made with a TH blade that are better than DH blade, if the smith making the DH blade is not doing it right. (if the hamon has areas that are too close to the edge, then the sword runs the risk of being fragile). Try posting the exact model, with the smith and a pic of sword, so you canget better advise. and this diagram (tho not the most inclusive), can help.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 6, 2009 15:53:26 GMT

I have the CS Grosse Messer and that thing does not care what the bleep you put in front of it...

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 6, 2009 16:14:07 GMT

I have the CS Grosse Messer and that thing does not care what the bleep you put in front of it... yes and it is listed as 1055 Carbon steel. like I said, decent smithing is very important. CS has strong products, the only complaint that i have heard on them is furniture fittings, but for a good blade, no problem, it can be fixed. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 6, 2009 16:38:14 GMT

YOu can abuse 1050 in alot of ways during the creation process, as well as te heat treat process. Unless things are done VERY wrong, which is obvious and common in alot of sub 300 chinese forges (but not all), it will be an OK blade. Expect no great performance however, it is not a high performance steel.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 6, 2009 17:08:31 GMT

For a monosteel, my preference is usually 1095 carbon. Again, as Sam, and I have stated.....smithing is everything, no matter how good the steel.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 6, 2009 18:17:49 GMT

For a monosteel, my preference is usually 1095 carbon. Again, as Sam, and I have stated.....smithing is everything, no matter how good the steel. When it comes to 1095, the smith and process is much more important as it is much finickier, 1050 is a very simple steel. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 6, 2009 19:49:52 GMT

WeaponEdge makes the gunto, and I'm guessing that you're getting it from Stromlo? He's a member, so perhaps he can answer the question as to just how well smithed these pieces are as WeaponEdge (an Indian forge) usually makes swords for re-enactors.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 7, 2009 0:15:46 GMT

Hm, perhaps that would be a good idea. I had asked him earlier for a close up of one of the gunto's mechanism; perhaps he can shed some light on their treatment.

M.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 7, 2009 3:24:18 GMT

Hm, perhaps that would be a good idea. I had asked him earlier for a close up of one of the gunto's mechanism; perhaps he can shed some light on their treatment. M. That's what I'd do. Personally, I can't wait to see this review! I love most things gunto. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 7, 2009 3:30:13 GMT

i own a few of cold steel 1055 swords and they perform fine. but like everyone is already saying, the smithing and process in which the blade was made is what matters.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 7, 2009 10:14:59 GMT

Hm, perhaps that would be a good idea. I had asked him earlier for a close up of one of the gunto's mechanism; perhaps he can shed some light on their treatment. M. That's what I'd do. Personally, I can't wait to see this review! I love most things gunto. Well, it will be a while; wont have money till later this month, it takes about two months to get anything from Weapon Edge (maybe longer as I'm doing an order with 2 others to split shipping costs), then I have to get it properly sharpened (by someone that isn't me), then I need to get a friend with a camera to come and do all the photography. But, here's to hoping it all goes well! M. |

|

|

|

Post by stromloswordsusa on Dec 7, 2009 11:51:39 GMT

Hi all, In response to some of the questions: The hardening on blades is TH, not DH. The steel I specify for my orders is 1050, the normal production swords are closer to 1040 or 1045. Honestly I think some I recieve have been batch made out of lower carbon steel but the tempering leaves them all very strong. I dont have rockwell HC for the swords but would like to get them independently verified (any volunteers?) I will have a few of the Shin Gunto models in the next few weeks and can post some additional pics. As the production is handmade, the production times vary and can be very lengthy esp if others have large orders in. They are supposed to pass on orders to me as distributor, but if they dont good luck, and hang in there with the waiting. I give discounts of $20per sword ordered that is not in stock for this reason. I offer another $10 off the price of each sword for SBG members, free shipping for orders over $350 - and also I now allow access to wholesale pricing for anyone providing initial order is over $1000. In short, I'll try work with you, and get what you want, and try answer any questions as I know the website is in need of updating! Regards, Rob www.stromloswords.com |

|

|

|

Post by Brendan Olszowy on Dec 7, 2009 12:19:59 GMT

|

|

|

|

Post by stromloswordsusa on Dec 7, 2009 12:27:36 GMT

I would have to check with weaponedge and trust the broken Indian/English conversation that followed. I would rather trust imperical testing on swords (ideally while I watch) or by trusted sources before I start quoting numbers to people on on the website.

Thanks,

Rob

|

|

|

|

Post by shadowhowler on Dec 7, 2009 12:46:16 GMT

I would have to check with weaponedge and trust the broken Indian/English conversation that followed. I would rather trust imperical testing on swords (ideally while I watch) or by trusted sources before I start quoting numbers to people on on the website. Thanks, Rob I find that admirable sir.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 7, 2009 13:29:38 GMT

Rob, I have a friend or two with rockwell testers, if you are interested shoot me a PM.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 7, 2009 15:34:36 GMT

For a monosteel, my preference is usually 1095 carbon. Again, as Sam, and I have stated.....smithing is everything, no matter how good the steel. When it comes to 1095, the smith and process is much more important as it is much finickier, 1050 is a very simple steel. Sam, I believe that you are totally correct on that, but as I said, that is just my personal preference.... that is where confidence in the smith comes into play. I will use Garrett as an example. The forge that he uses to make his blades does an excellent job. I reckon alot of production lines out there use the 1045, 1050, 1055, anf 1060 for the forgiving qualities you mentioned. But you know how some folks are, as myself, numbers can be impressive. I have a good sword made out of 1045 that is very durable. I believ that i would use it in combat if i ever had to. |

|